Fluid flow operation is an essential concept in fluid mechanics. It involves the study of the behavior of fluids, such as liquids and gases, as they move through a system. From the flow of water in a river to the movement of air in an airplane’s engine, fluid flow operation plays a crucial role in many aspects of our daily lives. In this blog post, we will provide an overview of fluid flow operation, its importance, and a conceptual approach to understanding it. We will also provide examples to help you better understand the practical applications of this concept. So, whether you are a student learning about fluid mechanics, or someone interested in the workings of fluid systems, this blog post is for you.

Fluid Mechanics is the study of the forces on fluids. These fluids might be either gaseous or liquid in nature. Fluid mechanics encompasses both fluid statics (the study of fluids at rest) and fluid dynamics (the study of fluids in motion). Although, fluid dynamics is known as fluid flow operation, which is an essential part of fluid mechanics.

Table of Contents

What is the Fluid flow operation?

Fluid flow is a fundamental concept in chemical engineering that refers to the movement of fluids through pipes or other channels. This is an important area of study because fluids are a crucial part of many industrial processes. In this article, we will discuss the basic principles of fluid flow, including the types of flow, the equations that govern fluid flow, and some practical applications.

Classification of fluids

Fluids can be classified as liquids or gases, and their behavior is governed by the principles of fluid mechanics. Fluids can be classified based on various properties such as their behavior, composition, and physical state. Some of the common classifications of fluids are:

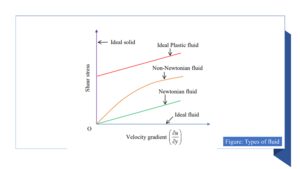

Newtonian and Non-Newtonian fluids: Newtonian fluids exhibit a constant viscosity under varying shear rates, while non-Newtonian fluids have a variable viscosity under different shear rates.

Ideal and Real fluids: Ideal fluids are hypothetical fluids that have zero viscosity, while real fluids have non-zero viscosity.

Compressible and Incompressible fluids: Compressible fluids are those that experience a change in volume with a change in pressure, while incompressible fluids maintain a constant volume under all pressure conditions.

Viscous and Non-viscous fluids: Viscous fluids resist deformation and flow slowly, while non-viscous fluids flow easily and do not resist deformation.

Dilute and Concentrated fluids: Dilute fluids contain a small amount of solute in the solvent, while concentrated fluids have a high amount of solute in the solvent.

Single-phase and Multiphase fluids: Single-phase fluids consist of only one phase, either liquid or gas, while multiphase fluids contain two or more phases.

Organic and Inorganic fluids: Organic fluids are those that contain carbon and hydrogen atoms, while inorganic fluids do not contain carbon and hydrogen atoms.

These classifications of fluids are important in understanding their behavior and properties and play a crucial role in the design and optimization of various chemical processes.

Types of flow

Different types of fluid flow occur in pipes or other channels. These types of flow are mainly classified based on the Reynolds number, which is a dimensionless quantity that characterizes the flow regime. The Reynolds number is defined as the ratio of inertial forces to viscous forces and is expressed as Re = (ρVD)/μ, where ρ is the fluid density, V is the fluid velocity, D is the characteristic length scale, and μ is the fluid viscosity. Some of the common types of flow are:

Laminar flow: Laminar flow is characterized by smooth, regular flow patterns and occurs at low Reynolds numbers. The fluid particles move in a straight line parallel to the pipe walls and do not mix.

Turbulent flow: Turbulent flow is characterized by irregular, chaotic flow patterns and occurs at high Reynolds numbers. The fluid particles move randomly and mix, resulting in higher frictional losses and pressure drops.

Transitional flow: Transitional flow occurs between laminar and turbulent flow and is characterized by fluctuating flow patterns. The difference between laminar, turbulent, and transitional flow can be understood from the below figure.

Steady flow: Steady flow occurs when the fluid properties remain constant with time.

Unsteady flow: Unsteady flow occurs when the fluid properties vary with time.

Compressible flow: Compressible flow occurs when the fluid density changes significantly due to changes in pressure and temperature.

Incompressible flow: Incompressible flow occurs when the fluid density remains constant under all conditions.

The type of flow that occurs in a particular situation depends on various factors such as fluid properties, flow velocity, and pipe geometry. Understanding the different types of flow is essential for designing and optimizing fluid flow systems in various industrial processes.

Industrial application of fluid flow operation

Fluid flow is an important aspect of many industrial processes and has various applications in different fields. Some of the common industrial applications of fluid flow are:

Transportation: Fluid flow is used for the transportation of various substances such as crude oil, natural gas, and water through pipelines.

Cooling: Fluid flow is used for cooling applications in various industries such as power generation, chemical processing, and electronics manufacturing. The fluid absorbs heat from the equipment or process and carries it away, thereby maintaining the desired temperature.

Heating: Fluid flow is used for heating applications in industries such as food processing, pharmaceuticals, and chemical manufacturing. The fluid is heated through a heat exchanger and then circulated through the process or equipment, thereby transferring heat to the material being processed.

Mixing: Fluid flow is used for mixing applications in various industries such as chemical processing, pharmaceuticals, and food manufacturing. The fluid is used to mix various substances and achieve the desired reaction or product.

Spraying: Fluid flow is used for spraying applications in industries such as agriculture, automotive, and aerospace. The fluid is sprayed onto the surface to achieve a desired effect such as coating, cleaning, or lubrication.

Pneumatic conveying: Fluid flow is used for pneumatic conveying applications in industries such as cement manufacturing and food processing. The fluid is used to transport solid materials through a pipeline by suspending them in a high-velocity air stream.

Hydroelectric power generation: Fluid flow is used for generating electricity through hydropower plants. The fluid, usually water, is used to turn the turbines, which generate electricity.

Oil and gas drilling: Fluid flow is used for drilling applications in the oil and gas industry. The fluid is used to cool and lubricate the drilling equipment and to transport the cuttings to the surface.

Waste treatment: Fluid flow is used for waste treatment applications in industries such as wastewater treatment plants and landfills. The fluid is used to transport and process the waste materials.

These are just a few examples of the industrial applications of fluid flow. With the increasing demand for efficient and sustainable processes, the importance of fluid flow in various industries is likely to grow in the coming years.

Formulas from fluid flow operation

There are several important formulas used in fluid flow operations, some of which are:

Bernoulli’s equation:

This equation relates the pressure, velocity, and height of a fluid in a steady flow. It is given as:

P + 1/2ρv² + ρgh = constant

Where P is the pressure, ρ is the density, v is the velocity, g is the acceleration due to gravity, h is the height, and the constant is the same for all points in the flow.

Reynolds number:

This dimensionless quantity is used to determine the type of flow (laminar or turbulent) in a fluid. It is given as:

Re = ρvd/μ

Where Re is the Reynolds number, ρ is the density, v is the velocity, d is the characteristic length, and μ is the dynamic viscosity.

Darcy’s law:

This equation relates the pressure drop across a porous medium to the flow rate and permeability of the medium. It is given as:

Q = -KAΔP/μL

Where Q is the flow rate, K is the permeability, A is the cross-sectional area, ΔP is the pressure drop, μ is the dynamic viscosity, and L is the length of the medium.

Hagen-Poiseuille equation:

This equation relates the pressure drop across a pipe to the flow rate and viscosity of the fluid. It is given as:

Q = πr⁴ΔP/8μL

Where Q is the flow rate, r is the radius of the pipe, ΔP is the pressure drop, μ is the dynamic viscosity, and L is the length of the pipe.

Friction factor:

This dimensionless quantity is used to calculate the pressure drop in a pipe due to friction. It is given as:

f = 64/Re

Where f is the friction factor and Re is the Reynolds number.

These are just a few examples of the formulas used in fluid flow operations. The choice of the formula depends on the specific application and the conditions of the flow.

Important Question and Answer

Important questions and answer from fluid flow operation in chemical engineering, which might be useful for competitive exams such as GATE and interviews.

Question: What is the difference between laminar and turbulent flow?

Answer: Laminar flow is characterized by smooth and predictable flow, where fluid particles move in straight lines and parallel layers. Turbulent flow, on the other hand, is characterized by irregular and chaotic flow, where fluid particles move in random directions and mix.

Question: What is the Reynolds number?

Answer: The Reynolds number is a dimensionless quantity used to determine the type of flow (laminar or turbulent) in a fluid. It is defined as the ratio of inertial forces to viscous forces and is given by Re = ρvd/μ, where ρ is the density, v is the velocity, d is the characteristic length, and μ is the dynamic viscosity.

Question: What is Bernoulli’s equation?

Answer: Bernoulli’s equation relates the pressure, velocity, and height of a fluid in a steady flow. It is given by the equation P + 1/2ρv² + ρgh = constant, where P is the pressure, ρ is the density, v is the velocity, g is the acceleration due to gravity, h is the height, and the constant is the same for all points in the flow.

Question: What is Darcy’s law?

Answer: Darcy’s law relates the pressure drop across a porous medium to the flow rate and permeability of the medium. It is given by the equation Q = -KAΔP/μL, where Q is the flow rate, K is the permeability, A is the cross-sectional area, ΔP is the pressure drop, μ is the dynamic viscosity, and L is the length of the medium.

Question: What is the Hagen-Poiseuille equation?

Answer: The Hagen-Poiseuille equation relates the pressure drop across a pipe to the flow rate and viscosity of the fluid. It is given by the equation Q = πr⁴ΔP/8μL, where Q is the flow rate, r is the radius of the pipe, ΔP is the pressure drop, μ is the dynamic viscosity, and L is the length of the pipe.

Question: What is the purpose of the Moody chart?

Answer: The Moody chart is used to calculate the friction factor in a pipe for turbulent flow. It is a graphical representation of the Colebrook equation, which relates the friction factor to the Reynolds number and the relative roughness of the pipe.

Question: What is the difference between head loss and pressure drop?

Answer: Head loss is the loss of potential energy of a fluid due to friction, turbulence, and other factors. Pressure drop, on the other hand, is the difference in pressure between two points in a fluid due to head loss or other factors.

Question: What is the purpose of a pump in a fluid flow system?

Answer: A pump is used to increase the pressure and flow rate of a fluid in a system. It is typically used to overcome head loss and maintain a desired flow rate or pressure.

Question: What is the purpose of a control valve in a fluid flow system?

Answer: A control valve is used to regulate the flow rate or pressure of a fluid in a system. It is typically used to maintain a desired set point or to control a process variable.

Question: What is the difference between laminar and turbulent boundary layers?

Answer: Laminar boundary layers are characterized by a smooth and thin layer of fluid near a solid surface, where the fluid particles move smoothly and predictably. Turbulent boundary layers, on the other hand, are characterized by a thicker and more chaotic layer of fluid near a solid surface, where the fluid particles move randomly and unpredictably.

Question: What is the definition of fluid flow?

Answer: Fluid flow is the motion of fluid particles caused by the application of a force.

Question: What is the difference between laminar flow and turbulent flow?

Answer: In laminar flow, the fluid flows in smooth, parallel layers with no disruption between layers, while in turbulent flow, the fluid flows in a chaotic, unpredictable manner with mixing and eddies.

Question: What is Reynolds’s number?

Answer: Reynolds number is a dimensionless quantity used to predict the flow regime of a fluid flow based on the ratio of inertial forces to viscous forces.

Question: What is the equation for pressure drop in a pipe?

Answer: The Darcy-Weisbach equation is commonly used to calculate the pressure drop in a pipe: ΔP = f (L/D) (ρv^2/2), where f is the friction factor, L is the pipe length, D is the pipe diameter, ρ is the fluid density, and v is the fluid velocity.

Question: What is the definition of hydraulic gradient?

Answer: Hydraulic gradient is the change in hydraulic head per unit of length along the direction of flow in a porous medium or a pipe.

Question: What is the definition of specific gravity?

Answer: Specific gravity is the ratio of the density of a substance to the density of a reference substance at a specified temperature.

Question: What is the definition of viscosity?

Answer: Viscosity is the measure of a fluid’s resistance to flow.

Question: What is the definition of head loss?

Answer: Head loss is the reduction in the total head of a fluid as it flows through a pipe due to frictional losses.

Question: What is the definition of cavitation?

Answer: Cavitation is the formation and subsequent collapse of vapor bubbles in a liquid flow, often resulting in damage to equipment and a decrease in flow efficiency.

Question: What is the Fluid Mechanics?

Answer: The study of forces acting on fluids is called fluid mechanics.

Question: What is the Stagnation point?

Answer: In fluid mechanics, a stagnation point is a point at which the velocity of the fluid is zero. Stagnation points occur when fluid is brought to a complete stop by an object. They are typically found on the surface of objects.

Conclusion

In conclusion, fluid flow is a critical area of study in chemical engineering. Understanding the basic principles of fluid mechanics and the equations that govern fluid behavior is essential for designing and optimizing industrial processes that involve fluids. With continued advances in technology and the increasing demand for efficient and sustainable processes, the study of fluid flow will continue to be an important area of research for chemical engineers in the future.

———————***************———————-

Must Read