Chemical Process Industries is an integral part of the manufacturing sector. They play a critical role in transforming raw materials into usable products that we use every day. With the increasing demand for new and improved products, the chemical process industries have become more important than ever. Chemical process industries (CPI) refer to the manufacturing processes involved in the production of chemicals, petrochemicals, polymers, and other related products.

The chemical process industries is a significant part of the global economy, providing products that are used in various sectors, such as pharmaceuticals, agriculture, food, textiles, and construction. This article aims to provide an overview of the chemical process industries, their history, types of products, and the manufacturing processes involved. In this blog post, we will introduce the chemical process industries and discuss some basic concepts related to them. We will explore the various processes involved in the chemical process industries and how they contribute to the products we use in our daily lives.

Table of Contents

History of Chemical Process Industries

The origins of the chemical process industries can be traced back to ancient civilizations, where natural resources such as minerals, plants, and animals were used to create dyes, pigments, and other chemicals. In the early modern era, the industrial revolution marked the beginning of the modern chemical industry, with the development of the first synthetic dye by William Henry Perkin in 1856.

During the early 20th century, the chemical industry experienced significant growth, with the development of new chemical compounds and materials such as plastics, synthetic fibers, and pharmaceuticals. The industry also played a critical role in supporting the Allied forces during World War I and World War II, producing essential materials such as explosives, medicines, and synthetic rubber.

List of Chemical Process Industries

Process industries are those industries that are involved in the production of products through chemical or mechanical methods. The following is a list of process industries:

- Chemical Industry: The chemical industry produces various chemicals that are used in different industries such as plastics, pharmaceuticals, cosmetics, and food.

- Petroleum Industry: The petroleum industry is involved in the extraction, refining, and distribution of petroleum products such as gasoline, diesel, and jet fuel.

- Food Industry: The food industry involves the production of various food products such as snacks, beverages, canned foods, and bakery products.

- Textile Industry: The textile industry produces fabrics, yarns, and other textile products using various materials such as cotton, wool, and synthetic fibers.

- Pharmaceutical Industry: The pharmaceutical industry produces drugs and medicines for the treatment of various diseases.

- Paper Industry: The paper industry produces different types of paper and paper products such as tissue paper, printing paper, and packaging materials.

- Steel Industry: The steel industry is involved in the production of steel and other metal products such as iron, aluminum, and copper.

- Cement Industry: The cement industry produces cement and concrete products for use in construction projects.

- Fertilizer Industry: The fertilizer industry produces fertilizers that are used in agriculture to improve soil fertility and crop yield.

- Plastics Industry: The plastics industry produces various plastic products such as packaging materials, toys, and household items.

- Rubber Industry: The rubber industry produces rubber products such as tires, hoses, and belts.

- Mining Industry: The mining industry is involved in the extraction of minerals and metals from the earth.

- Water Treatment Industry: The water treatment industry is involved in the purification and treatment of water for drinking and other uses.

- Renewable Energy Industry: The renewable energy industry produces energy from renewable sources such as wind, solar, and hydropower.

- Paint and Coatings Industry: The paint and coatings industry produces various paints, coatings, and varnishes for use in homes, buildings, and other structures.

These are just a few examples of process industries, and there are many others that are involved in the production of different products.

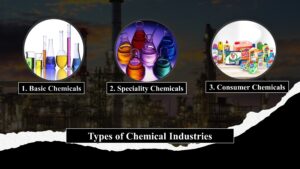

Types of Chemical Industries

Chemical industries can be broadly classified into three types based on their products: basic chemicals, specialty chemicals, and consumer chemicals.

Basic chemicals

These are chemicals that are produced in large quantities and used as building blocks for other products. Some examples of basic chemicals include:

- Petrochemicals: Ethylene, propylene, butadiene, benzene, toluene, and xylene are some examples of petrochemicals. They are derived from petroleum and natural gas and are used to produce plastics, synthetic fibers, rubber, and other products.

- Inorganic chemicals: Chlorine, sulfuric acid, ammonia, and sodium hydroxide are some examples of inorganic chemicals. They are used to produce fertilizers, textiles, paper, and other products.

- Polymers: Polymers are large molecules made up of repeating units called monomers. Some examples of polymers include polyethylene, polypropylene, polystyrene, and polyvinyl chloride. They are used to produce plastic products, such as bags, containers, and toys.

Specialty chemicals

These are chemicals that are produced in smaller quantities and are used for specific applications. Some examples of specialty chemicals include:

- Pharmaceutical chemicals: These are chemicals used to produce drugs and medicines. They include active ingredients, excipients, and other chemicals used in the formulation of medicines.

- Agrochemicals: These are chemicals used in agriculture, such as fertilizers, pesticides, and herbicides.

- Catalysts: Catalysts are substances that increase the rate of chemical reactions without being consumed themselves. They are used in various industrial processes, such as the production of plastics, fuels, and chemicals.

Consumer chemicals

These are chemicals used by individuals for personal care and household products. Some examples of consumer chemicals include:

- Cosmetics and personal care products: Shampoos, soaps, lotions, and makeup are some examples of consumer chemicals. They are used for personal hygiene and beauty care.

- Cleaning products: Household cleaners, such as detergents, bleach, and ammonia, are consumer chemicals used for cleaning purposes.

- Food additives: Food additives are chemicals added to food to enhance its flavor, color, texture, or shelf life. Some examples include preservatives, sweeteners, and flavorings.

Overall, chemical industries play a crucial role in modern society, providing essential products for our daily lives. From plastics and medicines to cleaning products and cosmetics, chemical industries have a significant impact on the global economy and our way of life.

The formula in Chemical Process Industries

In the subject of Chemical Process Industries, several formulas and equations are commonly used to analyze and design chemical processes. Here are some important formulas used in this field:

Material Balance Equation:

Input – Output = Accumulation

This equation represents the principle of conservation of mass and is used to determine the flow rates and compositions of various streams in a process.

Energy Balance Equation:

Input – Output = Accumulation

This equation represents the principle of conservation of energy and is used to calculate the energy transfer and heat exchange in a process.

Mass Fraction:

Mass Fraction = Mass of Component / Total Mass

A mass fraction represents the fraction of a component’s mass in a mixture or solution.

Mole Fraction:

Mole Fraction = Moles of Component / Total Moles

Mole fraction represents the fraction of a component’s moles in a mixture or solution.

Conversion:

Conversion = (Initial Moles – Final Moles) / Initial Moles

Conversion is a measure of the extent to which a reactant is converted to products in a chemical reaction.

Yield:

Yield = (Actual Yield / Theoretical Yield) x 100%

Yield represents the efficiency of a chemical reaction in producing the desired product.

Selectivity:

Selectivity = (Moles of Desired Product / Moles of Undesired Product) x 100%

Selectivity measures the extent to which a reaction produces the desired product compared to undesired by-products.

Heat Transfer Equation:

Q = mcΔT

This equation calculates the heat transfer in a process, where Q is the heat transfer, m is the mass, c is the specific heat capacity, and ΔT is the temperature change.

Reaction Rate Equation:

Rate = k[A]m [B]n

This equation represents the rate of a chemical reaction, where k is the rate constant, [A] and [B] are the concentrations of reactants, and m and n are the reaction orders with respect to A and B, respectively.

Ideal Gas Law:

PV = nRT

This equation describes the behavior of an ideal gas, where P is the pressure, V is the volume, n is the number of moles, R is the gas constant, and T is the temperature.

These are just a few examples of the formulas used in the field of Chemical Process Industries. The specific formulas used will depend on the process, system, and calculations being performed.

Manufacturing Processes in chemical process industries

The manufacturing processes involved in the chemical process industries can be broadly classified into the following categories:

Batch Processes: In batch processes, a fixed quantity of raw materials is added to the reactor vessel, and the reaction is allowed to proceed until completion. Once the reaction is complete, the product is removed from the vessel, and the reactor is cleaned for the next batch.

Continuous Processes: In continuous processes, raw materials are continuously fed into the reactor, and the reaction proceeds continuously until the desired product is obtained. Continuous processes are more efficient and cost-effective than batch processes.

Semi-Continuous Processes: Semi-continuous processes are a combination of batch and continuous processes, where raw materials are continuously fed into the reactor, but the reaction is allowed to proceed for a fixed duration.

Hybrid Processes: Hybrid processes are a combination of two or more types of processes, such as batch and continuous processes, to optimize the manufacturing process.

Chemical process industries (CPI) involve various manufacturing processes that transform raw materials into useful products. These industries have significant economic and environmental impacts, making it important to develop efficient and sustainable manufacturing processes. Here are some common manufacturing processes used in CPI:

Chemical Synthesis: This process involves the chemical reaction of raw materials to produce a new product. Examples of chemical synthesis include the production of ammonia from nitrogen and hydrogen and the production of ethylene from naphtha.

Fermentation: Fermentation processes are used to produce products such as alcohol, organic acids, and enzymes. In a fermentation process, microorganisms are used to convert sugars into the desired product. Fermentation processes are commonly used in the production of beer, wine, and antibiotics.

Polymerization: Polymerization processes are used to produce polymers from monomers. In a polymerization process, the monomers are reacted together to form long chains of polymers. Polymerization processes are commonly used in the production of plastics, rubber, and synthetic fibers.

Distillation: This process is used to separate and purify various chemicals based on their boiling points. It is commonly used in the production of petrochemicals, such as gasoline, diesel, and jet fuel.

Extraction: This process is used to extract a specific chemical from a mixture. It is commonly used in the production of natural products, such as vegetable oils and fragrances.

Crystallization: This process involves the formation of crystals from a solution. It is used in the production of various chemicals, such as salt, sugar, and pharmaceuticals.

Drying: This process involves the removal of moisture from a material. It is commonly used in the production of various chemicals, such as fertilizers, pigments, and food products.

Oxidation and Reduction: These processes involve the addition or removal of electrons from a molecule. They are commonly used in the production of various chemicals, such as hydrogen peroxide, chlorine, and sulfuric acid.

Electrolysis: This process involves the use of an electric current to drive a chemical reaction. It is commonly used in the production of metals such as aluminum, copper, and zinc.

Combustion: This process involves the burning of fuel to produce heat and other products. It is commonly used in the production of energy and chemicals such as sulfur dioxide and carbon dioxide.

In summary, the chemical process industries involve a wide range of manufacturing processes, each with its unique set of challenges and opportunities. Developing sustainable and efficient manufacturing processes is crucial for the future of these industries and their impact on society and the environment.

FAQ

Question: What is the chemical process industries?

Answer: The chemical conversion of raw materials during their processing into finished products.

Question: What are the 5 types of chemical industry?

Answer: The chemical sector in the United States is divided into five distinct segments: agricultural chemicals, basic chemicals, specialty chemicals, consumer products, and pharmaceuticals.

Question: What is an example of a chemical process industries?

Answer: Plastics, cleaning materials, cosmetics, paints and coatings, electronics, automobiles, and building materials are some examples.

Question: What is PLC in the chemical industry?

Answer: Programmable Logic Controllers, PLCs are digital electronic devices, that generally use programmable memories to store instructions and to carry out functions like timing, counting, logic, sequencing, and arithmetic in order to control machines and their processes.

Question: What are the 4 chemical processes?

Answer: The four basic types of chemical processes: synthesis, decomposition, single replacement, and double replacement.

Question: What are the two types of chemical industry?

Answer: Organic sector and inorganic sector.

Question: What is the list of process industries?

Answer: See above

Question: What is the largest chemical industry?

Answer: Badische Anilin und Sodafabrik (BASF) with 92,982 Chemical sales in USD (2021)

Question: Why is the chemical industry important?

Answer: Provides a variety of raw materials and building blocks for various industries, including those that produce textiles, paper, paint, soap and detergents, pharmaceuticals, agrochemicals, and more.

Question: Which chemical has the highest demand?

Answer: According to the World Trade Report, soda ash (40%) is the chemical that Indians consume the most, followed by caustic soda (38%) and hydrochloric acid (12%).

Question: Which is the number 1 chemical company in India?

Answer: Super Crop Safe

Question: Which is the king of chemicals in India?

Answer: Sulfuric acid (H2SO4) is referred to as the king of chemicals.

Question: Which chemical is the queen of chemicals?

Answer: The queen of organic chemistry is benzene.

———*****———

Must read